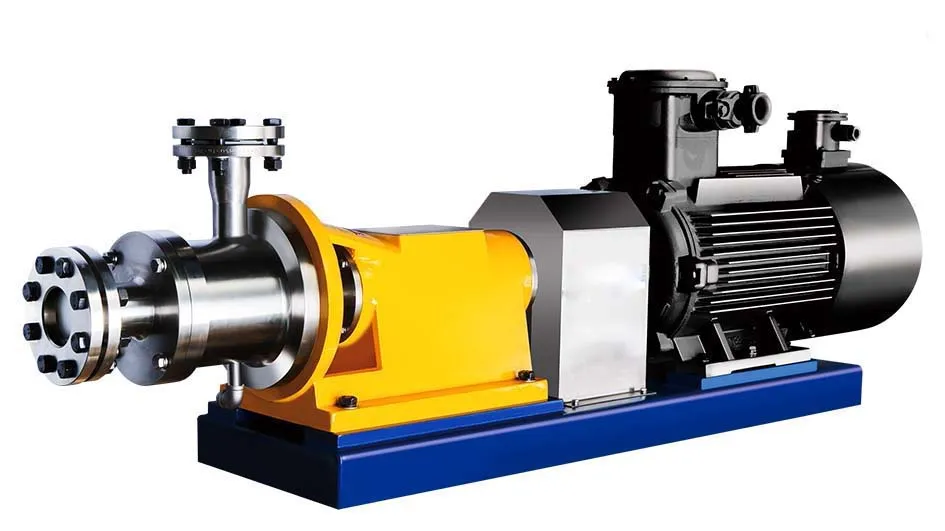

Cream pudding high shear emulsifier

Pudding cream emulsifying homogenizer

For pudding powder, carrageenan, carrageenan, carrageenan, l.b.g and other natural seaweed gum are used as coagulant (i.e. pudding stabilizer), SSL and t-95 are used as emulsifiers, and eggs, sugar, oil and other ingredients are mixed with water.

According to the calculation of 15% sugar added, the heat energy generated by each 15 gram weight pudding in the body is 8.93 kcal, while the daily heat energy supply of ordinary adults is about 2500 kcal, so the proportion of heat energy generated by pudding in the body is very low.

Working principle of high speed homogenizer for butter pudding high shear emulsifier and pudding emulsion

The high shear homogenizer for cream pudding is a process that one or more phases (liquid, solid, gas) are efficiently, rapidly and uniformly transferred into another immiscible continuous phase (usually liquid). In general, each phase is immiscible. When the external capacity is input, the two materials are reorganized into one phase. The strong kinetic energy generated by the high tangential velocity and the high frequency mechanical effect caused by the high speed rotation of the rotor is the combined action of mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tear and so on in the gap between the stator and the rotor, resulting in suspension emulsion, emulsion and foam. In this way, the immiscible solid phase, liquid phase and gas phase can be uniformly and finely dispersed and emulsified in a moment under the joint action of the corresponding mature process and appropriate additives, and finally stable high-quality products can be obtained after high-frequency cycling.